“No Surprise” Software Modeling

To address the demands of complex shapes, varying types of material and tight tolerancing, we use a 3D simulation technique that reduces manufacturing uncertainties and costs. Through the use of this application we are able to model your production process and machines in your own facility. This ensures your design can be produced by your specific production process and there are no surprises once production starts. |

|

Reduced Risk and Cost

Our simulation process captures potential errors in the stamping and production process and integrates the proposed design with the proposed production process. This eliminates the risk and costs of unexpected material and labor usage or the soft costs of quality control and warranty returns. |

|

Reduced Tryout Time and Faster Availability

The value of using the simulation process in parallel with a die design is that it validates that the part can be made using the materials and machinery concepts envisioned for that particular design. This reduces tryout time, accelerates availability of the die and typically reduces the costs of the end-to-end manufacturing process.

|

Project Success

While we know that design & engineering services are the key to project success, project management and control is the driver behind every project ensuring that details are captured and nothing “falls between the cracks”.

A project manager will be assigned to you that is responsible for your satisfaction and project success. They will be your single point of coordination, minimizing your time and involvement while communicating to you your projects progress at regular intervals.

Our project managers are senior staff members that have many years in the tool and die business. In additions to their technical expertise they have excellent customer communication skills focused on project coordination and customer satisfaction.

|

|

|

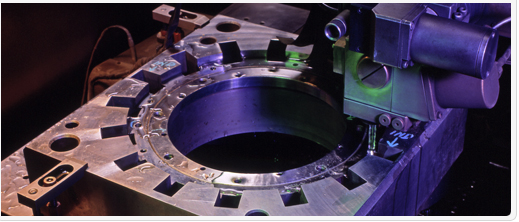

This video demonstrates the final result of a deep draw process used to stamp an oil pan in one operation. The various shading in the video represents varying amounts of material flow, validating the capability of the proposed process. This state- of- the- art simulation software accounts for key production variables including:

- Press Size

- Materials

- Production Sequence

|

Tools Used

Stroke Speed

Error Margin

|

|

|