|

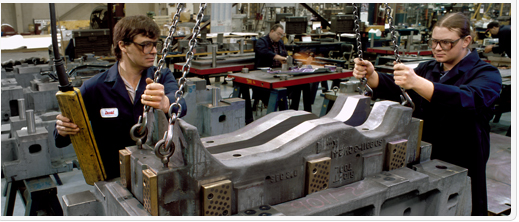

Die Maintenance & Repair Services

As you know, a die experiences wear & tear. This can cause wrinkles, mismatched parts, burrs, etc., all resulting in quality control issues and higher costs. We can trouble shoot your die problems and correct them all within your production schedule. |

|

Reverse Engineer A Spare

We have both the staff that can diagnose and repair remedial problems and also the engineering talent and tools to reverse engineer your tools and make spare details if necessary. Service and repair is available around the clock to respond and assist during planned maintenance periods or during emergency conditions. |

Sometimes dies break and cause a crash, shutting down a key part of your production process. As a full-service organization, Right Tool is prepared to help you with these operational issues and potential emergency situations to get you back in operation as quickly as possible. In some cases, tools have a tendency to break and a "maintenance & repair" strategy is not adequate to minimize downtime. This situation can be accommodated by having an on-site spare to immediately replace a deteriorating or failing detail. |

|

Contract Journeyman Services

Right Tool & Die provides a helping hand and can assist with reducing bottlenecks during peak demand. A journeyman resource can work on location at your facility, supervised by your management, or they can provide leadership for your staff for internal projects or repair issues.

Our staff is versed in contemporary die making practices. These skilled resources can be available on a short or long-term basis to suit your schedule. |

|

|