|

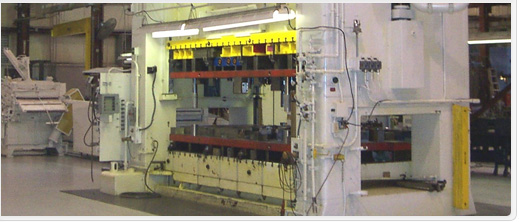

Quality Process Standards

Every die maker must invest in rigorous quality control procedures and equipment. In that regard, Right Tool & Die is no different than our competition. Yet we take QC one step further.

Quality control begins in our CAD/CAM department, where our specialists study every part design to optimize the end product for its production requirements. We also prepare capability studies or work with prototype shops to test prospective parts so customers can be assured the final stamping will actually perform as expected. During manufacture, parts are continually checked by our die makers and our QC department. Once the die is completed, our die technicians will work with the customer on-site to set up and adjust the die to meet all manufacturing requirements and processing procedures.

|